KANSAS CITY, MISSOURI, US – The US Department of Agriculture has deemed feed ingredients a negligible to moderate risk for the introduction of African swine fever virus in the United States. In addition, there has been research to suggest that feed mills can potentially disseminate endemic diseases, such as pathogens like Salmonella, porcine epidemic diarrhea virus (PEDV), porcine deltacoronavirus (PDCoV), or Seneca valley virus (SVV), throughout swine production systems. Given this information, there has been a focus on implementing biosecurity practices for multiple areas within the feed mill and some areas of emphasis include:

- Ingredient sourcing

- Receiving practices

- Drivers and delivery

- Feed handling

- Human movement

Although biosecurity practices/processes are being implemented in these areas, there are limited resources for measuring the effectiveness of these processes in terms of feed mill biosecurity for pathogen control. In addition, a limitation to implementing such strategies is the sampling methodology utilized to detect biological pathogens in feed ingredients or complete feed and on surfaces within a feed mill environment.

Feed serving as a fomite for disease has been a topic of discussion for veterinarians, production companies, and feed mills since it was speculated that a contaminated batch of feed introduced PEDV into North America. Ideally, a feed mill could use the same sample for nutritional quality analysis in addition to testing for the pathogen of interest. However, a problem with utilizing this type of sample for biological pathogen identification is that biological pathogens like mycotoxins, bacteria, and viruses are heterogeneously distributed in a single load of feed.

This concept of heterogeneous mixture, or sometimes referred to as “hot spots,” of biological pathogens of interest in feed is illustrated in Figure 1 of a feed tote with contamination illustrated as the red circle in the lower left corner. The purple cylinders on the tote picture illustrate a possible single pull sample for nutritional analysis visualizing that sometimes, most likely due to chance, the biological pathogen contamination is correctly identified from the feed container.

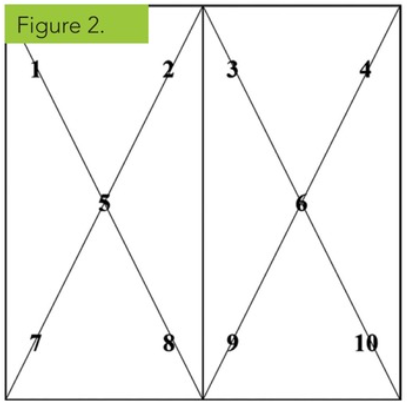

Therefore, when sampling feed for these pathogens of interest, a methodology similar to the Association of American Feed Control Officials (AAFCO) has been effective at identifying PEDV and ASFV in swine feed. This method consists of taking 10 probe samples of feed and combining them into a single composite sample and offers a solution to monitor for biological pathogens if concerned about potential contamination in feed ingredients or complete feed. Figure 2 demonstrates how probes should be positioned when looking down at the container, and inserted at varying depths, to account for the heterogeneous mixture of biological pathogens of interest.

Environmental samples offer another solution to proactively monitor biological pathogens of interest for a feed mill. Environmental samples can specifically target areas that have high foot traffic like feed delivery trucks, areas where workers congregate like the feed mill office or break room, or surfaces that can move like brooms or tires on a forklift. Focus on these areas in the feed mill is due to research suggesting inanimate objects or people involved at the feed mill or feed delivery system contribute to the spread of pathogens like ASFV, PDCoV or PEDV.

There are several options to obtain environmental samples for viruses: 1) hand sampling with cotton gauze or Swiffer cloth or 2) paint roller covers utilizing an extension set. For bacterial pathogens, sponge sticks are the methodology of choice for the FDA. In the United States, the FDA considers animal feed to be adulterated when it is contaminated with a Salmonella serotype that is considered to be pathogenic to the animal intended to consume the feed and the animal feed will not undergo other commercial processes that will kill the Salmonella (FDA, 2013).

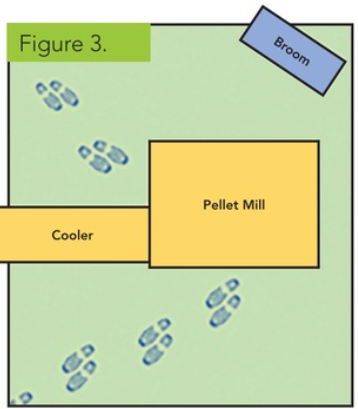

The FDA evaluates these on a case-by-case basis but if concerned for Salmonella species, the sponge stick sampling methodology for bacteria is highly encouraged. There are also studies suggesting that stick sponges are better at collecting bacterial pathogens while cotton material is better for viral pathogens. Environmental samples can sample a wide range of surfaces and locations within a feed mill or production system. Environmental samples are classified into zones depending upon the location of the sampling surface. Take, for example, Figure 3, which is a rough blueprint of the second floor of a feed mill. The pellet mill and cooler, yellow in color, are considered feed contact surfaces because those surfaces within the machinery have direct contact with feed. The surfaces green in color are classified as non-feed contact surfaces since they are located next or close to feed contact surfaces but have no direct contact with feed. Some examples of non-feed contact surfaces include the floor by the pellet mill, the ceiling above the cooler, and the wall next to the pellet mill or similar surfaces of that nature. Transient surfaces, depicted in blue, are surfaces that can move within the feed mill environment, and in Figure 3 are depicted by worker’s shoes and a broom. More examples of transient surfaces are feed delivery truck tires, interior of the semi-truck cabs of the feed delivery trucks, or other similar surfaces.

After developing an understanding for sample types, one needs to develop the objectives of the sampling program to determine how to use the information that is collected. Surveillance is defined as the ongoing systematic and continuous collection, analysis, and interpretation of health data, allowing epidemiologists to follow in time and space the health status and some of the risk factors associated with diseases for a given population, for use in the planning, implementation, and evaluation of disease control measures.

Surveillance sampling often is utilized to evaluate the risk of a certain event occurring and to designate action if set points are exceeded. For example, surveillance is used to screen tonsils of pigs for foreign animal disease while surveillance also is used to screen carcasses at a packing plant for diseases that could impact human health. Surveillance most often is utilized to look for diseases in a region or country that would like to remain free from the disease in question given the financial and health implications of that disease. When thinking about the role a feed mill has for livestock production, it would be in the best interest for a feed mill to understand if it is serving as a source of disease for its customers and therefore would benefit from surveillance sampling.

If a feed mill has a suspected contamination, then it would need to transition to or initiate a suspected contamination sampling procedure. A suspected contamination sampling event aims to identify potential areas of contamination, then identify and implement strategies to reduce the suspected contamination. A suspected contamination sampling event should only be pursued when surveillance thresholds have been met or exceeded.

As part of the system, in this case, since the surveillance threshold has been met or exceeded, the feed mill or production system will transition into a suspected contamination sampling event. For this resource, surveillance prevalence rates were set for a monthly basis, and since it is believed that there’s suspected contamination at the feed mill, the sample size based on prevalence rates will switch to a weekly basis to increase the frequency of the sampling. For the next week, the feed mill will substitute surveillance sampling for suspected contamination sampling that will have a different focus depending upon the results from surveillance sampling.

A suspected contamination sampling event needs to be implemented quickly so results accurately portray the source of contamination and to reduce the potential of further dissemination of suspected contamination. For example, if receiving results from the lab on a Tuesday that confirms the surveillance threshold as met or exceeded, the appropriate amount of samples needs to be prepared Tuesday evening, sampling conducted Wednesday and/or Thursday (depending upon logistics and labor), and samples shipped or submitted by Thursday evening or Friday morning at the latest.

Sample size is another important question that needs to be determined for sampling protocols. Sample size recommendations based on the severity of the pathogen of interest and probability of feed serving as a source of pathogen of interest for the feed mill or production system can be found at www.ksufeed.org. Example sample sizes were calculated utilizing the sampling to detect disease formula in the surveillance sampling portion. As a reminder, these suggestions can be tailored to fit a production system and the information to do so is listed within this document.

Despite the low risk, swine production systems have focused on feed mill biosecurity to control any disease spread between feed mills and production sites via feed delivery. However, in addition, there aren’t many user-friendly or consistent options when considering potential sampling resources. For example, a feed mill could consult the literature, but that requires time to read the articles, and when reading these articles, sampling techniques vary between research groups. This led the Kansas State University Feed Safety Team to develop a set of K-State Feed Safety Sampling Resources.

These resources are either standard operating procedures or additional resources depending on the need of the person accessing these resources. Standard operating procedures provide instructions on assembling, collecting, logging, and submitting samples, while the additional resources guide sample size, sample locations, tests, and test interpretation.

The standard operating procedures focus on taking actionable steps so anyone can collect either environmental or feed samples at the feed mill. The additional resources focus more on the theory behind sampling so veterinarians, feed mill managers, or nutritionists can decide the number of samples needed and what the results from these samples mean for the feed mill.

The goal of these resources was to make it easier for anyone wanting to develop and implement a sampling program for a feed mill if concerned about pathogen control. Anyone can access these resources through KSUfeed.org by clicking on the K-State Feed Safety Sampling Resources link.

Chad Paulk is an assistant professor of feed science and management in the Department of Grain Science and Industry at Kansas State University. He may be reached at cpaulk@ksu.edu.